•

financing the railway line between the mine and the dam

•

rehabilitation of the Kisangani cement plant

•

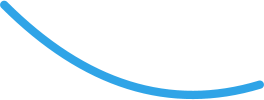

the river upstream of the dam, between Kisangani and Kindu,will be navigable

•

a high manometric height of the hydroelectric dam will provide several MW of energy

•

A canal will be dug from Kisangani to the dam to allow the navigability of the Congo River

and gain 10m of manometric height of the dam

•

The location of the dam must be the one that minimizes the sum of the costs of the dam

and the canal, example of a dam that minimizes the cost of the canal (layer)

•

The products of the excavation of the canal will participate in the construction of the gravity

dam

•

This dam will connect the two banks of the rivers by a road and a railway.

•

Part of the hydroelectric power will produce hydrogen by the direct reduction of itabirites

•

The methane gas from Lake Kivu transported by pipeline will provide the complement by formatting

•

The steel produced will be transported by barge down the Congo River

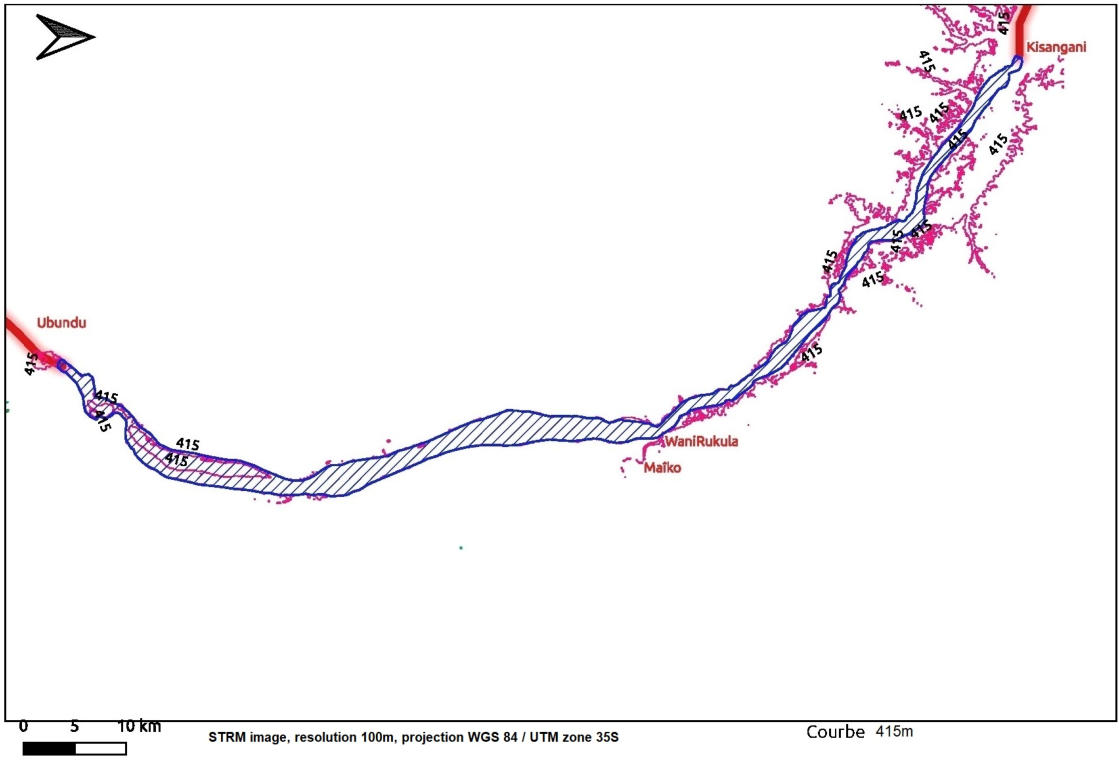

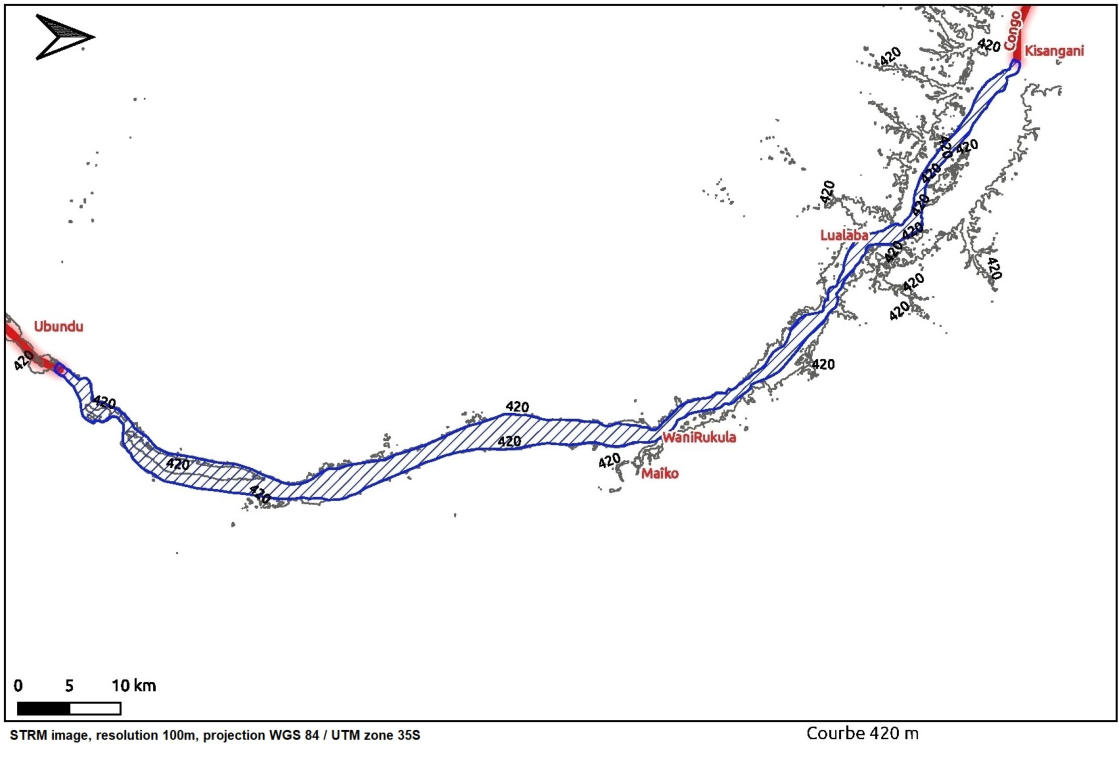

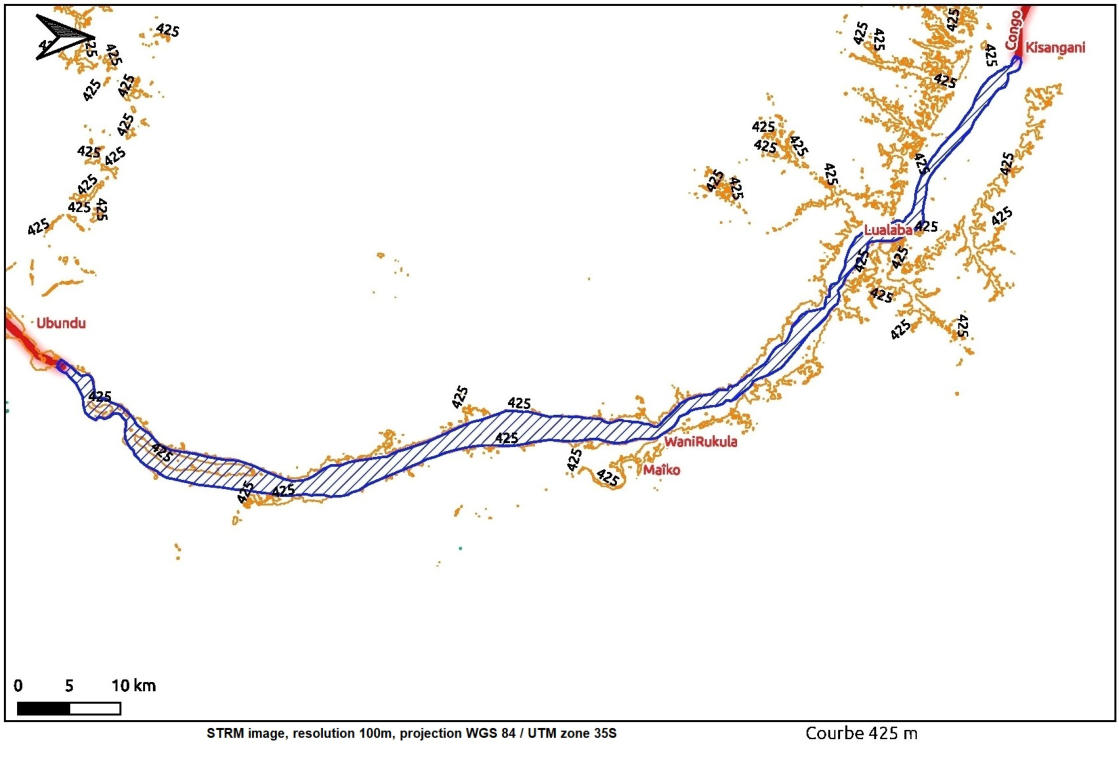

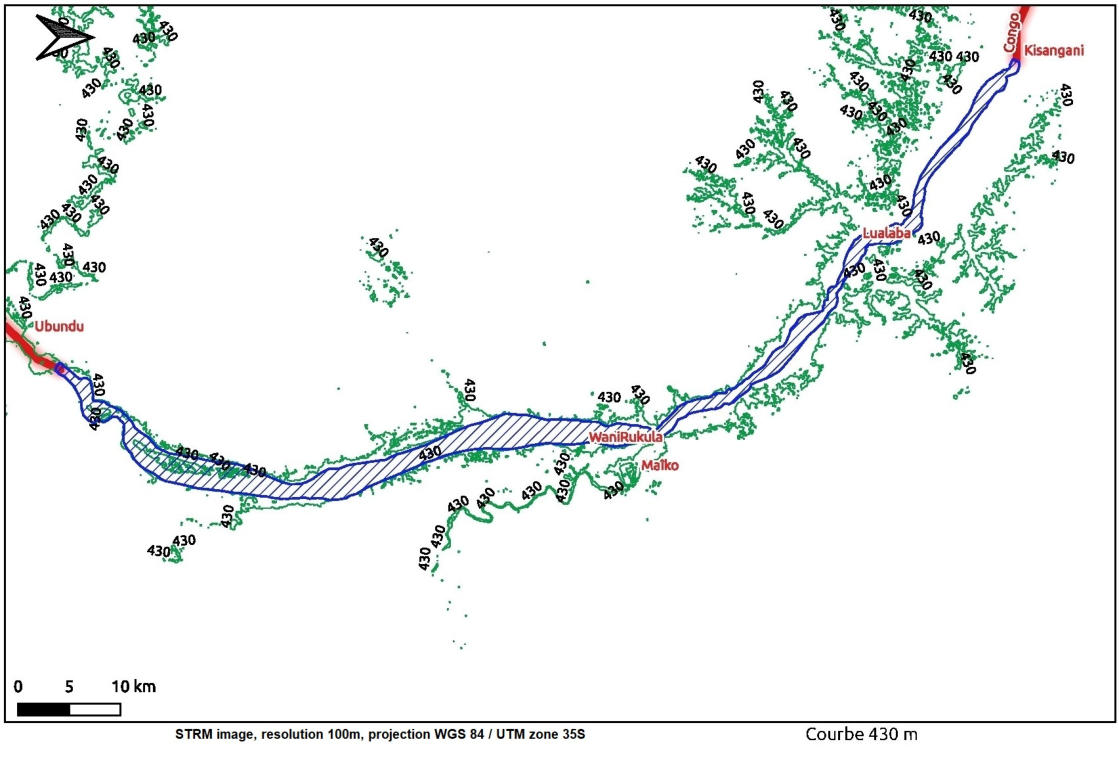

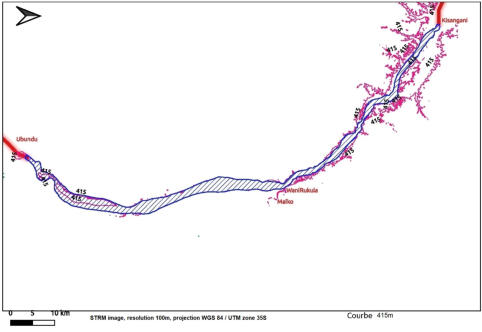

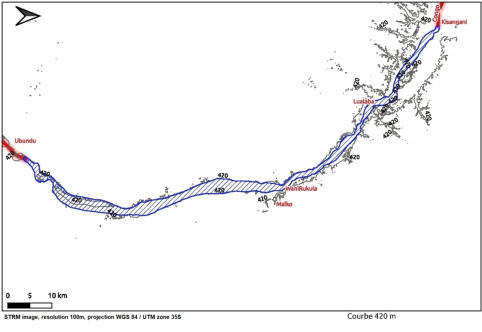

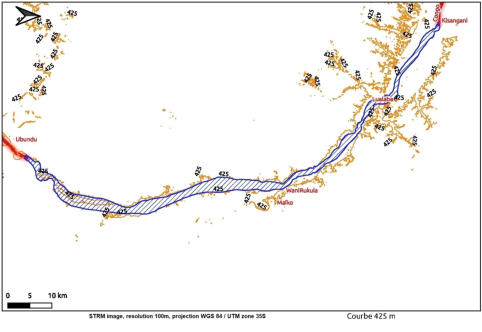

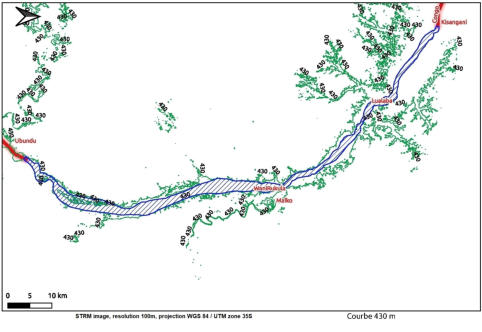

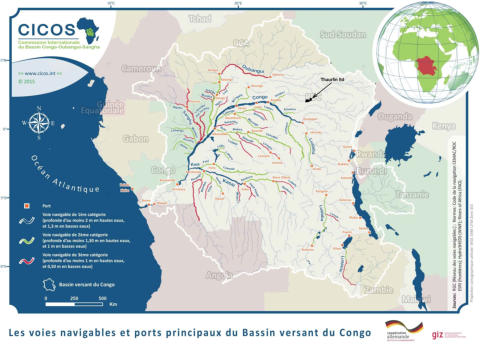

The flooded areas depends on the manometric height of the dam 30m (415-383) 35m (420-383) 40m (425-383) 45m (430-383) (made by Yves Malongo)

(40m seems the best, the flooded area near Kisangani upstream of the dam can be limited by the construction of a dike)

The local enhancement of the iron deposit will finance the development of the whole

Province by offering it a new green steel industry

PROJECT TO EXPORT 50Mt PER YEAR OF HIGH-GRADE IRON ORE

By river according to an innovative transport that optimizes its efficiency and safety cf

http://www.mbomo-mining.com/Iron-ore-export.pdf

Investments in infrastructure secured by the very high-grade Banalia iron ore deposit which has already been surface prospected in 1974.

This iron deposit was to supply the

Maluku steelworks

which was a failure because of its very poor location.

Surface prospecting was carried out by the Italian and Belgian companies SICAI/TRACTIONNEL, cf

http://www.mbomo-mining.com/SICAI.pdf

The prospecting results have been entered into the Excel file published on

http://www.mbomo-mining.com/SICAI-TRACTIONNEL.xlsx

According to this report, the probable reserves would be 969Mt@65.55%Fe

Analysis

of

the

report

published

on

http://www.mbomo-mining.com/Iron-deposit.pdf

shows

that

they

underestimate

the

real

exploitable

reserves.

It

is

legitimate

to

write

that

prospecting

by

drilling

will

reveal

certain

economically

exploitable

reserves

of

2bt

at

a

very high grade of around 65% Fe, ensuring 40 years of export at 50Mt per year.

A win/win partnership with the Country

The local enhancement of the iron deposit will finance the

development of the whole Province by offering it a new green

steel industry

•

financing the railway line between the mine and the dam, passing through Kisangani

•

the stripping of the itabirites will participate in the construction of the dam

•

rehabilitation of the Kisangani cement plant

•

The river upstream of the dam, between Kisangani and Ubundu,will be navigable

•

a high manometric height of the hydroelectric dam will provide several MW of energy

•

A canal will be dug from Kisangani to the dam to allow the navigability of the Congo

River and gain 10m of manometric height of the dam

•

The location of the dam must be the one that minimizes the sum of the costs of the

dam and the canal, example of a dam that minimizes the cost of the canal (layer)

•

This dam will connect the two banks of the rivers by a road and a railway.

•

Part of the hydroelectric power will produce hydrogen by the direct reduction of

itabirites

•

The methane gas from Lake Kivu transported by pipeline will provide the complement

by formatting

•

The steel produced will be transported by barge down the Congo River

The flooded areas depends on the manometric height (map by Yves Malongo)

30m (415-383) 35m (415-383) 40m (415-383) 45m (415-383)

(40m seems the best, the flooded area near Kisangani upstream of the dam

can be limited by the construction of a dike)

PROJECT TO EXPORT 50Mt PER YEAR OF HIGH-GRADE IRON ORE

By river according to an innovative transport that optimizes its efficiency and safety

cf

http://www.mbomo-mining.com/Iron-ore-export.pdf

Investments

in

infrastructure

secured

by

the

very

high-grade

Banalia

iron

ore

deposit

which

has

already

been

surface

prospected

in

1974.

This

iron

deposit

was

to

supply

the

Maluku

steelworks

which

was a failure because of its very poor location.

Surface prospecting was carried out by the Italian and Belgian companies SICAI/TRACTIONNEL,

cf

http://www.mbomo-mining.com/SICAI.pdf

the results are synthesized on :

http://www.mbomo-mining.com/SICAI-TRACTIONNEL.xlsx

According to this report, the probable reserves would be 969Mt@65.55%Fe

Analysis

of

the

report

published

on

http://www.

mbomo-mining.com

/Iron-deposit.pdf

shows

that

they

underestimate

the

real

exploitable

reserves.

It

is

legitimate

to

write

that

prospecting

by

drilling

will

reveal

certain

economically

exploitable

reserves

of

2bt

at

a

very

high

grade

of

around 65% Fe, ensuring 40 years of export at 50Mt per year.